Polyurethane Mos Upholstery Lub Rooj Cushion PU Ua Npuas Ncauj Filling Tshuab

| Lub npe: | High Pressure Pu Ua Npuas Ncauj Tshuab | Foaming Txoj Cai: | Siab Siab Cua Hom |

|---|---|---|---|

| Mixing Ratio Ntau: | 1: 5 ~ 5: 1 (kho tau) | Kev txhaj tshuaj tso zis (sib xyaw piv 1: 1): | 110-540g / s |

| Ua Npuas Ncauj Hom: | Ua Npuas Ncauj | Daim ntawv thov: | Anti Fatigue Mats |

| Lub teeb siab: | Upholstery Seat Cushion Foaming Tshuab, Upholstery Cushion PU ua npuas ncauj filling tshuab, 540g / s PU ua npuas ncauj filling tshuab | ||

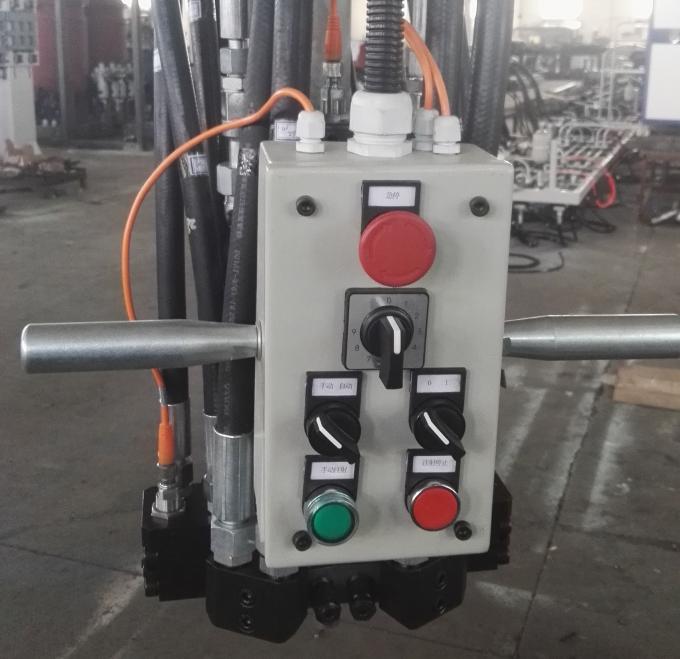

Polyurethane Mos Foam Sib Tw Tsheb UpholsteryRoojCushion Ua Tshuab Siab Siab PU Foaming Tshuab Paub meej ntawm Foam Flexible Foam Txhaj Tshuab:Lub taub hau sib xyaw: Txais Kaus Lim Kauslim SPU tus kheej tu L hom sib xyaw lub taub hau, kho lub koob hom nozzle, V-puab txau orifice, kev kub siab sib tsoo sib xyaw ua ke, uas ua kom muaj kev sib xyaw ua ke ntawm cov khoom sib xyaw.Hluav taws xob tswj qhov system: Txais mcgs txiv neej-lub computer interface, teem lub sij hawm txhaj tshuaj, kuaj lub sij hawm thiab siab lub sij hawm thiab lwm yam Temperature control unit: Kub tswj chav tsev yog tsuas yog siv rau temp.tswj cov khoom siv ob qho tib si thiab ua rau lawv mus rau hauv cov qauv kev sib koom ua ke.Specifications ntawm High Pressure Foam Tshuab:

| Tsis muaj. | Yam khoom | Technical Parameter |

| 1 | Ua npuas ncauj thov | PU ua npuas ncauj |

| 2 | Raw khoom viscosity (22 ℃) | POL ~ 2500mPas ISO ~ 1000mPas |

| 3 | Txhaj tshuaj | 10 ~ 20Mpa (kho tau) |

| 4 | Cov zis txhaj tshuaj (sib piv 1: 1) | 160-800g / s |

| 5 | Mixing ratio ntau | 1: 3-3: 1 (kho tau) |

| 6 | Lub sijhawm txhaj tshuaj | 0.5 ~ 99.99S (yog rau 0.01S) |

| 7 | Khoom siv kub tswj yuam kev | ± 2 ℃ |

| 8 | Rov txhaj tshuaj raug | ± 1% |

| 9 | Muab lub taub hau | Kauslim SPU 1218-2K, plaub roj hoses, ob lub tog raj kheej roj |

| 10 | Hydraulic system | Tso zis 10L / min System siab 10 ~ 20MPa |

| 11 | Tank ntim | 250L |

| 12 | Input zog | Peb-theem tsib-xaim, 380V 50HZ |

Khoom siv lub ntsiab technical yam ntxwv:1. Cov khoom siv tshuaj sib xyaw lub taub hau tuaj yeem txav mus rau pem hauv ntej thiab rov qab, sab laug thiab sab xis, nce thiab nqis; 2.Siab rab koob li qub ntawm cov ntaub ntawv dub thiab dawb raug kaw tom qab sib npaug kom tsis txhob muaj qhov sib txawv siab

3. Sib nqus coupler txais cov cuab yeej siv hluav taws xob ruaj khov ruaj khov, tsis muaj qhov to thiab kub nce

4. Tsis siv neeg tua phom tom qab txhaj tshuaj

5. Cov txheej txheem txhaj tshuaj muab 100 qhov chaw ua haujlwm, qhov hnyav tuaj yeem raug teeb tsa ncaj qha kom tau raws li kev tsim khoom ntawm ntau yam khoom.

6. Lub taub hau sib xyaw siv ob qhov sib thooj hloov tswj, uas tuaj yeem paub meej cov khoom txhaj tshuaj.

7. Tsis siv neeg hloov ntawm zaus converter mos pib mus rau siab thiab tsawg zaus, qis-carbon, txuag hluav taws xob, kev tiv thaiv ib puag ncig, zoo heev txo lub zog noj.

8. Tag nrho cov digital, modular kev koom ua ke tswj tag nrho cov txheej txheem, raug, nyab xeeb, intuitive, ntse thiab humanization Daim ntawv thov ntawmpolyurethane ua npuas ncauj txhaj tshuab: Polyurethane ua npuas ncauj tuaj yeem siv rau txhua yam ntawm cov rooj zaum hauv tsev, xws li cov rooj zaum noj mov thiab lub rooj zaum rooj zaum, mus rau lub tsheb thiab lub nkoj nkoj;thiab vim tias qhov zoo thiab cov neeg siv khoom txaus siab yog peb qhov tseem ceeb tshaj plaws, peb lub hom phiaj xa cov khoom lag luam uas ua kom muaj kev nplij siab tshaj plaws.

Daim ntawv thov ntawmpolyurethane ua npuas ncauj txhaj tshuab: Polyurethane ua npuas ncauj tuaj yeem siv rau txhua yam ntawm cov rooj zaum hauv tsev, xws li cov rooj zaum noj mov thiab lub rooj zaum rooj zaum, mus rau lub tsheb thiab lub nkoj nkoj;thiab vim tias qhov zoo thiab cov neeg siv khoom txaus siab yog peb qhov tseem ceeb tshaj plaws, peb lub hom phiaj xa cov khoom lag luam uas ua kom muaj kev nplij siab tshaj plaws.  Cov lus teb ntawmpolyurethane txhaj tshuaj molding tshuab

Cov lus teb ntawmpolyurethane txhaj tshuaj molding tshuab